China tells chipmakers to use homegrown chipmaking tools for 50% of new capacity — decree designed to squeeze foreign suppliers out of supply chain

But there is a catch, or two.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

China has quietly introduced a rule under which chipmakers must use at least 50% domestically produced equipment when adding new semiconductor manufacturing capacity, reports Reuters. The move could potentially reshape procurement decisions, accelerate local tool adoption, and squeeze foreign suppliers out of the Chinese market.

However, there are a number of catches with this requirement: firstly, authorities grant waivers for advanced fabs; secondly, Chinese industry cannot produce enough litho systems, if the numbers via Reuters are accurate.

The rule is not published in any formal regulation, but in recent months, companies seeking government approval to build or expand fabs have been instructed to prove that at least half of their equipment spending is directed to Chinese suppliers. Applications that fail to meet the threshold are typically rejected, according to people familiar with the process. In fact, officials told applicants that 50% is a baseline rather than a target as the long-term objective is to exclusively use domestic wafer fab tools.

However, regulators allow case-by-case flexibility when domestic alternatives are constrained, which is perhaps the main catch about the rule. The requirement is applied most strictly to production lines used to make chips via mature process technologies, whereas advanced nodes receive temporary exemptions due to gaps in local tool availability, particularly when it comes to lithography equipment.

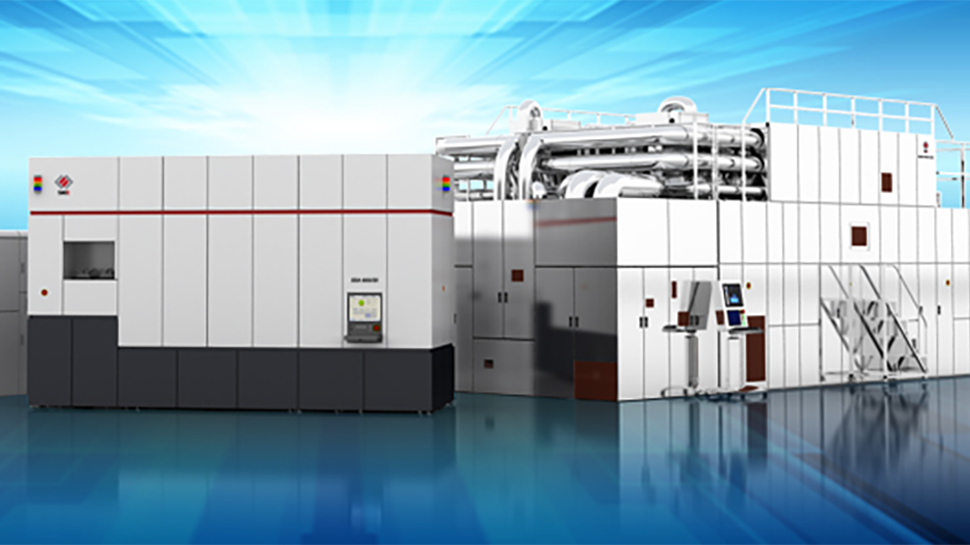

Speaking of lithography tools, state-linked chipmakers placed 421 orders for domestically produced lithography machines and their components this year at combined value of about ¥850 million ($121.3 million), according to Reuters. While the number 421 looks substantial, it includes both new systems and spare parts, which does not give an idea how many new tools were actually ordered.

To put the value into context, ASML's dry ArF tools used to produce chips on mature nodes cost around $27.9 million per unit on average (based on the company's Q4 FY2024 results), whereas KrF systems cost around $14.46 million per unit. By contrast, ASML's latest immersion DUV (ArF) lithography scanners used to make chips on advances process technologies cost $82.5 million per unit on average. With Chinese-made litho tools we do not usually talk about immersion lithography, but rather about dry ArF or KrF machines (China's best demonstrated tools are 28nm-capable, but these do not seem to be in mass production now). That said, the combined value shows that the Chinese industry can only produce rather cheap litho systems for outdated process technologies and even they are hardly made in significant quantities.

$121.3 million is approximately eight ASML KrF litho machines. Even if Chinese manufacturers have managed to cut costs of these mature tools by half (which is probably impossible), it means that they could only produce 16 of such tools in 2025. By contrast, ASML built 152 KrF steppers, 65 i-line tools, 28 ArF dry scanners, 129 ArF scanners, and 44 EUV scanners in 2024.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

-

Mindstab Thrull I still think China having the capability to be fully independent can only be a good thing. I can't imagine they'll be behind the Western world for long, and besides, if the situation between China and the US stays on its present course, they'll eventually prove they don't need us, at which point the tariffs et al are largely irrelevant, and if Nvidia gets to reasonably sell there again, China gets to say "sure but it needs to be compatible with what we have now. Can you do that?" And maaaaybe - one can only hope - this will force pricing down. And if they can't - or won't - I'm sure AMD or Intel will be willing to take advantage of that!Reply -

Gururu Time to bring Canadian and Mexican resources up to speed in the sector. Keep it in North America.Reply