AMD's 96-core beast with watercooling engraved into CPU joins car and industrial parts in a 2,000W direct die cooling setup — $12,000 CPU runs at 5.3 GHz, devours 1,300W, and still runs cooler than your gaming PC

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

When off-the-shelf cooling can't tame the world's best CPUs, you have to start thinking outside of the box. Chinese YouTube channel Geekerwan has puthe Ryzen Threadripper Pro 9995WX, a 96-core Zen 5 behemoth that costs almost $12,000, to its limits with an eye-opening DIY cooling solution. It features a custom CNC-machined integrated heat spreader (IHS), automotive-grade cooling components, an industrial chiller, and a 37-gallon water tank.

IHS modifications aren't new in hardware circles. We've previously seen the transformation implemented on processors such as the Core i9-14900KS. However, the Ryzen Threadripper Pro 9995WX is a different beast in every sense of the word. The Zen 5 flagship workstation processor isn't just substantially larger than a typical consumer chip; it also features a more complex AMD chiplet design and requires additional engineering effort.

Behind every successful project lies countless hours of preparation. In Geekerwan's case, it took extensive trial-and-error and thermal simulations to arrive at the perfect direct-die IHS design for the Ryzen Threadripper Pro 9995WX. Rather than risking delidding a $12,000 processor, Geekerwan reached out to Tony Yu, General Manager of Asus China, to borrow an IHS for study. The channel purchased several old Ryzen Threadripper 1900X processors and sacrificed them to test various microchannel patterns to identify the most efficient design.

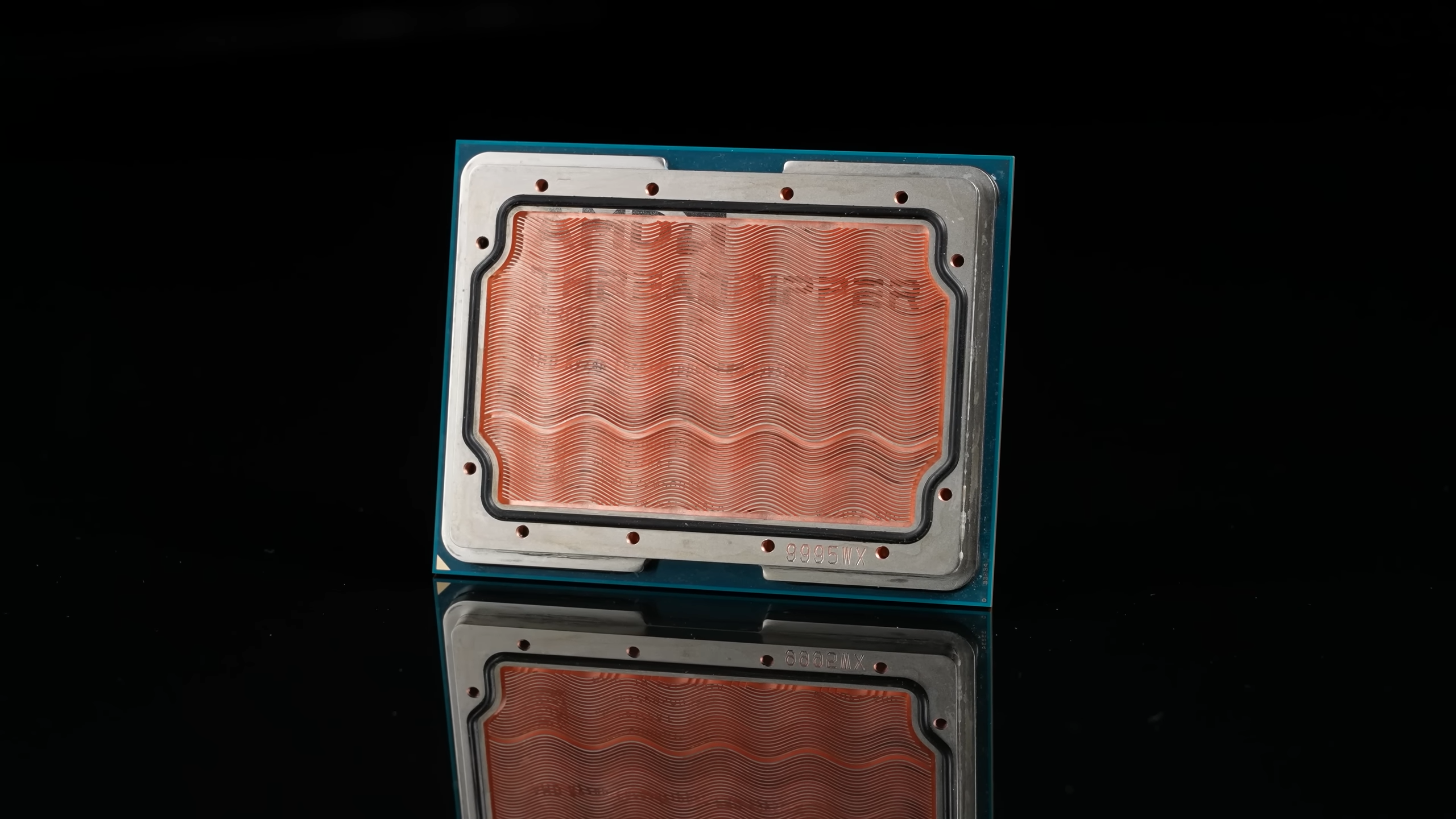

The first challenge was to determine the optimal microchannel depth. Because the Ryzen Threadripper Pro 9995WX's IHS is 0.6mm thicker than the Ryzen Threadripper 1900X, the microchannels must be slightly deeper. Geekerwan used a precision 0.3mm CNC cutter to carve ultra-thin 0.15mm cooling fins with 0.3mm of spacing. The result is a high-density design that maximizes heat transfer.

The team tested 1.5mm, 2.0mm, and 2.5mm cuts on the Ryzen Threadripper 1900X IHS, achieving 82.1, 81.2, and 80.4 degrees Celsius, respectively. The logic is that deeper cuts improve cooling performance, but overdoing it will compromise the IHS's structural integrity and increase the risk of deformation under water pressure. Therefore, Geekerwan settled on a depth of 2.0mm to preserve at least 2.1mm of the heat spreader for safety margins.

The next challenge was to select a microchannel pattern. Straight microchannels are the industry standard, but Geekerwan's computer simulations showed a better design. Since the author planned to use industrial components for the cooling solution, the liquid velocity and pressure would logically exceed those of normal liquid coolers. By adopting wavy S-shaped microchannels, the heat dissipation area can increase significantly by up to 20%.

Testing on the Ryzen Threadripper 1900X showed up to a 1.2 degrees Celsius improvement between the traditional straight and wavy microchannels. Getting the design from concept to reality was grueling. It took 19 hours of CNC machining inside the Taikan T-700S and the destruction of 14 fragile 0.3mm cutting tools to get the Ryzen Threadripper Pro 9995WX ready. The final result was a beautiful array of one hundred fins of varying lengths on the $12,000 processor's IHS.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

The water block also required careful analysis. The Ryzen Threadripper 1900X and Ryzen Threadripper Pro 9995WX don't share the same design. The two CCDs in the Ryzen Threadripper Pro 9995WX sit at the chip's far edges, unlike the CCDs in the Ryzen Threadripper 1900X that cluster in the center. Due to the chiplet design and the die placement, Geekerwan needed to rethink the water block's design.

Rather than using a conventional dual-tube water block, Geekerwan tested an alternative three-tube configuration on the Ryzen Threadripper 1900X: one central inlet feeding two side outlets, one on each side. The design ensures equal heat dissipation across the two CCDs. The results were impressive, with temperatures dropping by up to 5.1 degrees Celsius compared with two-tube designs.

Geekerwan capitalized on the findings and added one additional tube produce an innovative four-tube design in a cross pattern. Liquid flows through the two central inlets, which are directly over the two CCDs, absorbs heat, and exits through the two side outlets. Powering the ambitious solution are two 50W Bosch water pumps, one salvaged from a Mercedes and the other from a Geely. Meanwhile, an industrial chiller does the heavy lifting and cools the liquid to zero degrees Celsius as the liquid flows through the loop and back to the 37-gallon reservoir.

Ryzen Threadripper Pro 9995WX Overclocking Benchmarks

| Header Cell - Column 0 | 5.3 GHz Overclock | 5.2 Overclock | PBO |

|---|---|---|---|

Frequency | 5.325 GHz | 5.2 GHz | 4.7 GHz |

System Power Consumption | 1,634W | 1,552W | 951W |

Cinebench R23 Score | 205,332 | 194,300 | 174,137 |

Cinebench 2024 | 10,080 | N/A | N/A |

Cinebench 2026 | 41,478 | N/A | N/A |

Geekerwan overclocked the Ryzen Threadripper Pro 9995WX to 5.325 GHz, drawing around 176W and idling at just five degrees Celsius. The liquid temperature was approximately two degrees Celsius, so heat transfer from the 96-core chip to the water tank was highly efficient. During the Cinebench 2024 and Cinebench 2026 runs, the processor consumed around 1,340W with core temperatures oscillating between 30 degrees and 50 degrees Celsius. The entire system was pulling a little over 1,700W.

The performance gains were logically substantial. The Ryzen Threadripper Pro 9995WX at 5.3 GHz delivered up to 18% higher multi-core performance than the stock PBO setting, which had the cores running at around 4.8 GHz. Against the global overclocking leaderboards at HWBot, Geekerwan's overclocked Ryzen Threadripper Pro 9995WX ranked 7th in Cinebench R23, a hairline behind a Ryzen Threadripper Pro 7995WX at 6.2 GHz under liquid nitrogen. In Cinebench 2024 and Cinebench 2026, the Zen 5 chip came in third and second places, respectively, and trailed a Ryzen Threadripper Pro 9995WX at 5.7 GHz and an Xeon 698X at 4.9 GHz.

Geekerwan's project shows that you don't always need exotic liquid helium or liquid hydrogen cooling to chase world records. Sometimes, a little bit of ingenuity and engineering can go a long way. But for those of us who lack access to either, we can always look forward to next-generation AIO liquid coolers, such as Cooler Master's 360² (360 x 360mm), which claims to dissipate up to 2,000W of heat.

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

-

Stomx This just confirms that overclocking high end workstation chips has zero sense. Cooling them for extended longevity or reduced noise has increased and increased sense. Also solutions to use these kilowatts instead of disposing them to heat the atmosphere are welcome. Soon we will have 256-core chips which are alrady in testing, then 500 which are in development before we all switch on GPU dumped from the first generations of upgrading every few years AIReply -

bit_user This is a lot more interesting to me than liquid nitrogen overclocking - which is neat in a sort of "hold my beer" sense, but lacks any practical value, whatsoever.Reply -

bit_user Reply

I don't follow what you're trying to say here, but the peak power was only 1340 W. On a per-core basis, that would be equivalent to running a 9950X at 223W, which pretty much exactly matches what that CPU will do at stock settings:Stomx said:Cooling them for extended longevity or reduced noise has increased and increased sense.

Source: https://www.techpowerup.com/review/amd-ryzen-9-9950x/23.html

So, I think longevity shouldn't be significantly compromised, especially considering the low peak temperature of 50C! Seriously, do you know how hot those CPUs normally run? My 9600X idles near 50C! I certainly don't have liquid cooling on it, but it just drives home the points that this is not at all a high temperature and also that his cooling is exquisitely efficient!

Given the amount of effort that went into this feat, I think you don't have to worry about a lot of copycats.Stomx said:Also solutions to use these kilowatts instead of disposing them to heat the atmosphere are welcome.

First of all, 256-core is the Zen 6C, not full-size Zen 6. The big version should top out at 192 cores, due to having 12 cores per CCD.Stomx said:Soon we will have 256-core chips which are alrady in testing, then 500

Secondly, I don't know how much more room for scaling there is. Zen 6 is moving to the N2 node. We could expect to see another bump when they move to the node beyond that, but we might start to see their core counts plateauing and perhaps they refocus more on SMT or a different ISA. -

purposelycryptic I know the math makes sense, but it still somehow terrifies me that the overclocked processor alone draws more peak power than my entire dual-Xeon home server, including GPU and 24 HDDs.Reply -

Pierce2623 Reply

I mean old school 12 core Xeons just don’t use a ton of power compared to a 96 core behemoth with 12 chiplets, each of which probably has more transistors than one of your Xeons. These Epycs can easily go over 500w on air cooling.purposelycryptic said:I know the math makes sense, but it still somehow terrifies me that the overclocked processor alone draws more peak power than my entire dual-Xeon home server, including GPU and 24 HDDs. -

Stomx Reply

Only 1340W...:). How clueless you are:bit_user said:I don't follow what you're trying to say here, but the peak power was only 1340 W. On a per-core basis, that would be equivalent to running a 9950X at 223W, which pretty much exactly matches what that CPU will do at stock settings

Seriously, do you know how hot those CPUs normally run?

STH forum: "Water cooling of 0.5-1 kW processors"

https://forums.servethehome.com/index.php?threads/water-cooling-of-0-5-1-kw-processors.52619/ -

alan.campbell99 Reply

Something I'd like to see happen as well. I'd suspect it's highly unlikely if not impossible for 100% heat to electricity conversion but some level of conversion would be good. I did read recently about a material under study that appeared to achieve conversion without needing a thermal gradient like a typical TEG, just tried looking for the article but as yet didn't find it.Stomx said:Also solutions to use these kilowatts instead of disposing them to heat the atmosphere are welcome.

Random aside, that's reminding of this one player back during Action Quake 2 days detailing his PII overclocking with Peltier devices. -

DS426 Reply

Yep, just like I said in another topic as heat recapture pertains to the scale of data centers. A 1.3 KW workstation here and there is one thing, but 300 MW+ datacenters have a lot more heat on there hands, even if it's too low-temp for things that rely on the Rankine cycle (other solutions like district heating as utilized in cold places like Finland already employ this, but hotter climates require more creativity...).alan.campbell99 said:Something I'd like to see happen as well. I'd suspect it's highly unlikely if not impossible for 100% heat to electricity conversion but some level of conversion would be good. I did read recently about a material under study that appeared to achieve conversion without needing a thermal gradient like a typical TEG, just tried looking for the article but as yet didn't find it.

Random aside, that's reminding of this one player back during Action Quake 2 days detailing his PII overclocking with Peltier devices. -

DS426 Reply

I agree. Being able to provide this much cooling continuously 24/7 is more useful for real-world purposes.bit_user said:This is a lot more interesting to me than liquid nitrogen overclocking - which is neat in a sort of "hold my beer" sense, but lacks any practical value, whatsoever. -

bit_user Reply

I just skimmed a little bit, but that thread seems to have some good info. People there seem to agree it's not as insurmountable as the first poster implies.Stomx said:Only 1340W...:). How clueless you are:

STH forum: "Water cooling of 0.5-1 kW processors"

https://forums.servethehome.com/index.php?threads/water-cooling-of-0-5-1-kw-processors.52619/

Also, I don't appreciate being called "clueless". As I've pointed out in another thread as well, the surface area of these CPUs is a lot greater than a desktop CPU. That's not to trivialize the challenge, but just to point out that it involves a proportionately larger area. That makes the problem much more tractable than it might initially seem.