MIT-developed 3D printer can output a fully functional electric motor in a single process — team only needed to magnetize the linear motor after printing, motors cost just 50 cents each

Are we going to be able to 3D print completed engines in the future?

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

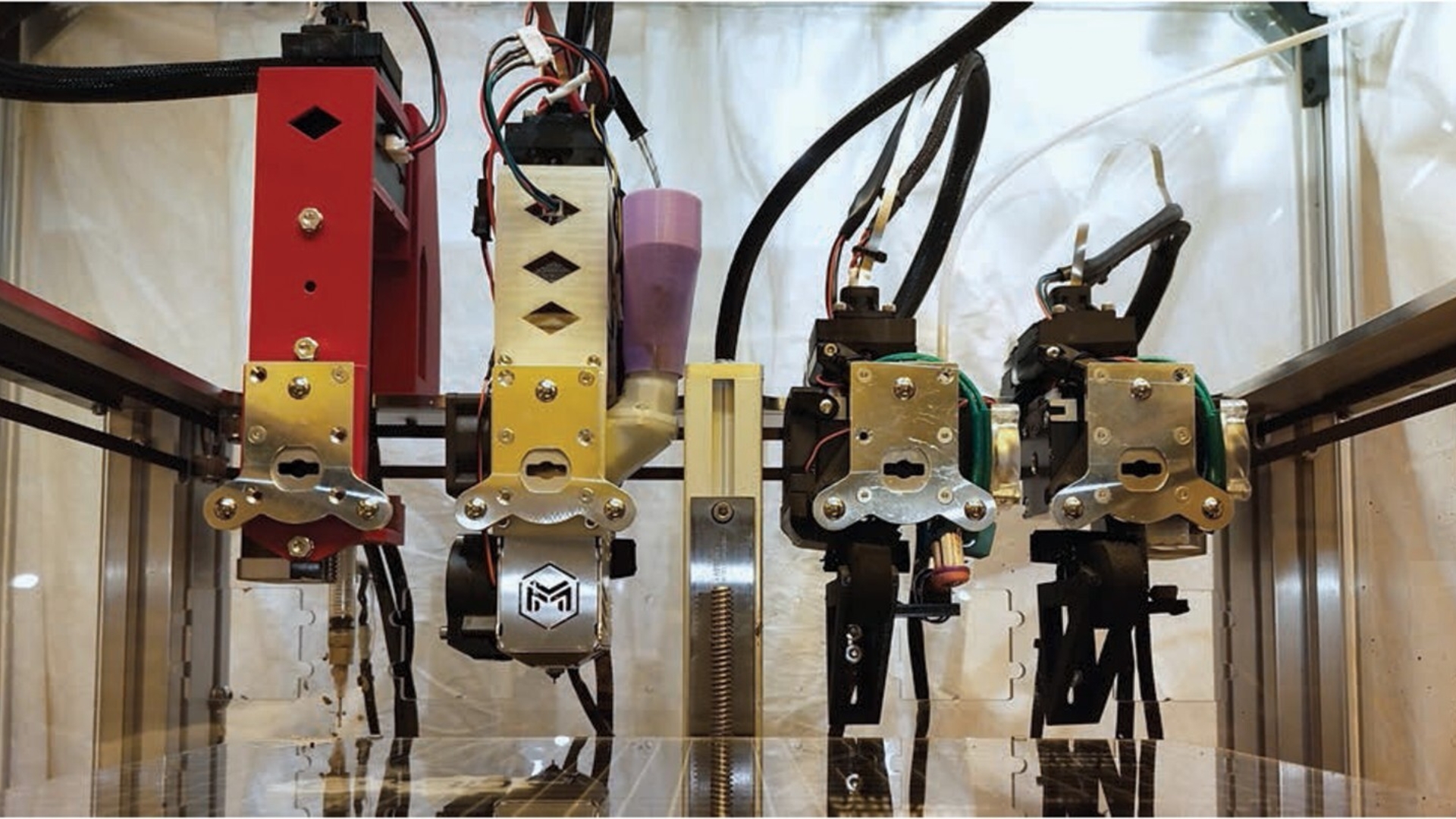

A team of researchers from the Massachusetts Institute of Technology (MIT) have developed a 3D printer that is capable of printing a fully functional linear motor in just a few hours. According to the paper published on Virtual and Physical Prototyping, the device is equipped with four different extruders — a filament extruder, a pellet extruder, an ink extruder, and a heater — and outputted five different materials — dielectric, electrically conductive, soft magnetic, hard magnetic, and flexible. The team aimed to build a multi-model, multi-material extrusion 3D printer that can build an electric motor with as few steps as possible.

Most existing extrusion 3D printers can only switch between two different materials, so MIT News reported that the team built their own system and retrofitted to an existing printer. They then used that to build a linear motor in about three hours, which only needed to be magnetized post-printing to become fully functional. More importantly, the final product worked just as well or even better than those that were built using traditional manufacturing methods, and the total cost in materials amounted to just about 50 cents.

When using traditional methods, building a one-off prototype can take several weeks to half a year, especially if you need custom tools and equipment. But with this new 3D printing method, you can cut that down to just one day. The researchers also mentioned that it’s useful for making replacement parts, especially for items that aren’t readily available locally. So, instead of relying on a global supply chain that would take weeks to months to deliver, especially with disruptions happening worldwide, you can just find a schematic or diagram of the item that needs replacement (or even build one yourself) and print it as needed.

“This is a great feat, but it is just the beginning. We have an opportunity to fundamentally change the way things are made by making hardware onsite in one step, rather than relying on a global supply chain. With this demonstration, we’ve shown that this is feasible,” Dr. Luis Fernando Velásquez-García, one of the senior authors of the research paper told the publication. He later added, “Even though we are excited by this engine and its performance, we are equally inspired because this is just an example of so many other things to come that could dramatically change how electronics are manufactured.”

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get 3DTested's best news and in-depth reviews, straight to your inbox.