Harvard scientists invent a new 3D printing technique for soft robotics—rotational multi-material printing produces muscle-like structures capable of being programmed to twist, lift, or bend

A new spin on robotics, thanks to a novel 3D printing method

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

A group of Harvard engineers has reached a new breakthrough in both 3D printing and soft robotics. A novel 3D printing method, created by the team, enables the production of entirely flexible 3D-printed structures capable of twisting and reshaping as needed.

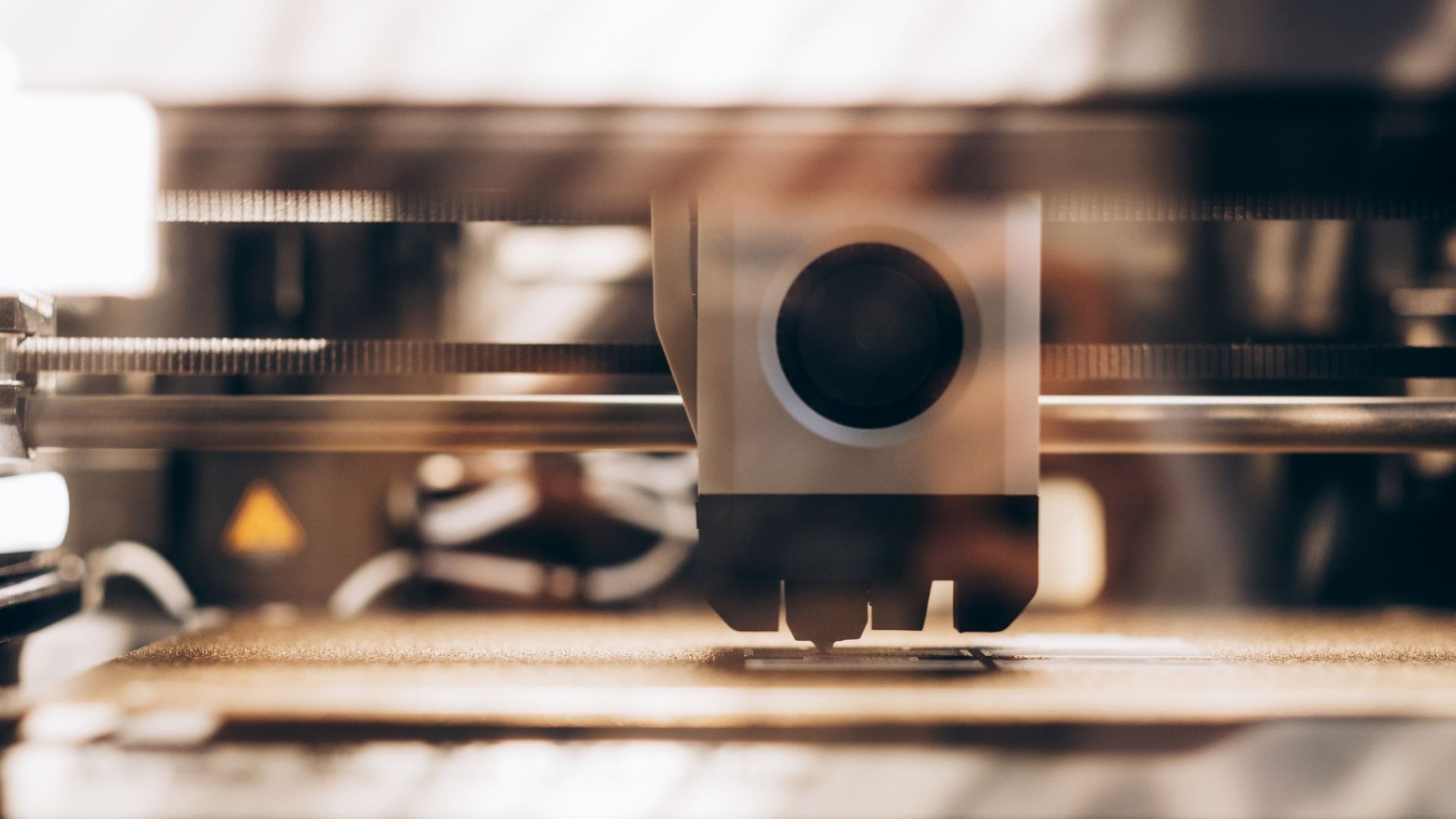

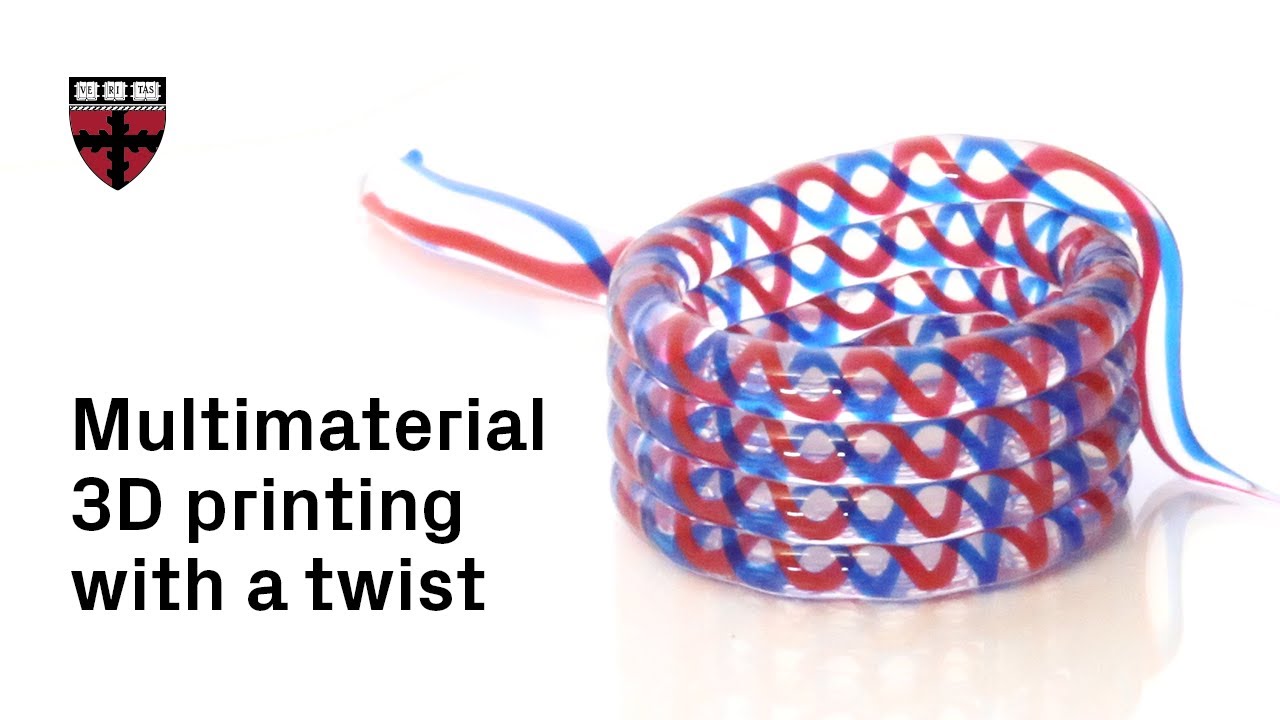

This new technique, developed by former postgraduate student Natalie Larson and graduate student Jackson Wilt at the John A. Paulson School of Engineering and Applied Sciences combined multiple existing techniques to develop a novel approach named rotational multi-material 3D printing. This method deposits multiple materials via a single nozzle that rotates continuously during printing.

This approach enables the team to assess how the materials integrate structurally during printing by fine-tuning the nozzle’s configuration, rotational speed, and flow rate. The robust outer layer, made of a tough polyurethane, shields the poloxamer core, characterized as a polymer material similar to hair gel. Once printing finishes, the gel is rinsed away to form a set of hollow tubes that can be controlled to function as muscles, inflated with air or liquid to induce various movements.

The intricacy of the design even enables integrated motion logic—the structure can be engineered to bend or twist in a predetermined manner. According to Wilt, this is achieved by employing two materials that can be "rotated to program the direction the robot bends when inflated." The researchers employed a flower-shaped spiral actuator that unfurls when inflated, Along with a hand-shaped gripper whose fingers can wrap around an object, to show its effectiveness.

If the process can be scaled industrially, this 3D printing approach for soft robotics offers two major benefits: speed and simplicity. Historically, soft robots have been made by pouring flexible materials into a mold and bonding them layer upon layer. Instead of depending on this lengthy process that demands numerous individual parts and sections, a 3D printer could produce a complex, flexible structure in one go and embed movement logic directly. Inside it.

Larson and Wilt’s work has the potential to transform robotics and influence multiple industries—if they can launch it successfully. Their research, featured in the Advanced Materials journal, has now been covered by a filed patent.

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

-

edzieba I was wondering what new work Larson et. Al. Had done, but no, this is the paper from 3 years ago.Reply