Chinese scientists 3D print tiny items in half a second using holographic light fields — scientists precision fabricate complex millimeter-scale objects in record time

Spinning the light source, instead of the material, has some benefits, too.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

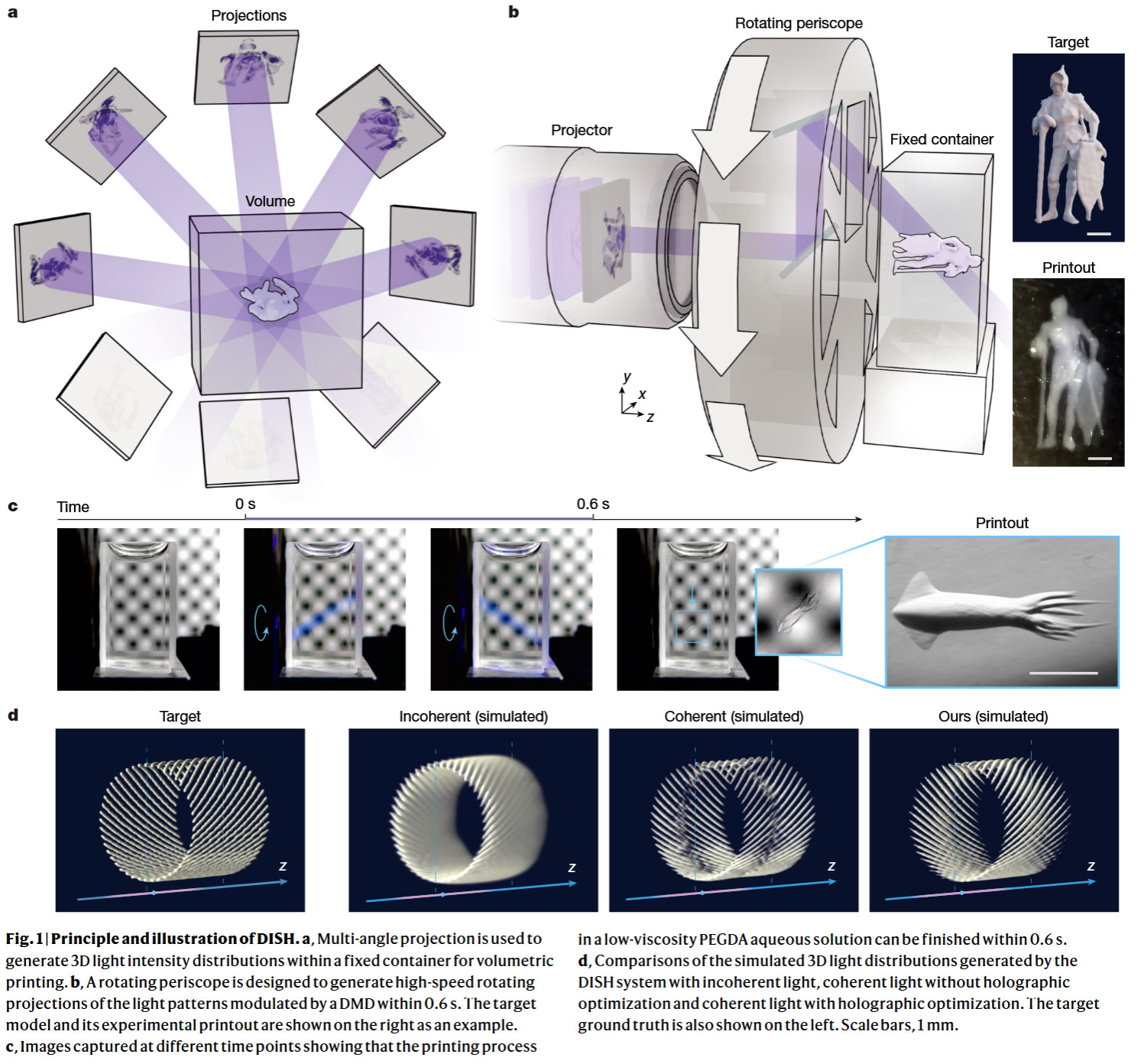

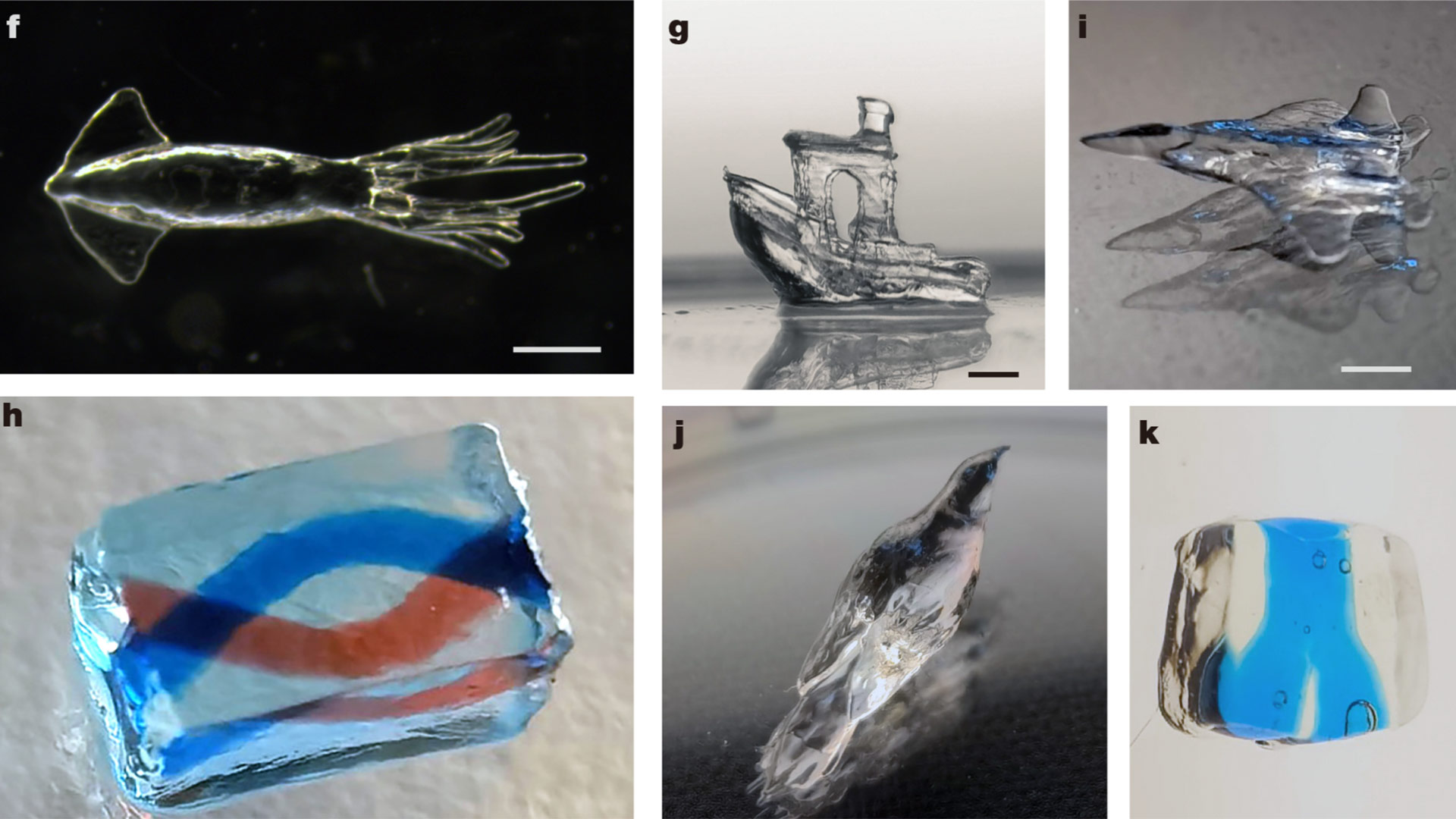

A team of scientists have revealed a new technique for the super-high-speed 3D printing of complex objects. The Tsinghua University-based team say they can 3D print complex millimeter-scale objects “within only 0.6s,” in an academic paper published by Nature earlier this week. The key advance behind this incredibly rapid feat of additive manufacturing has been dubbed the digital incoherent synthesis of holographic light fields (DISH).

3D printing is great for producing small-scale product runs on-demand. Even in 2026, it can still take a machine tens of minutes or even hours to output a complex, detailed, precisely honed shape that can be used in scientific research, medical, or other precision-sensitive fields. But thanks to DISH, and the team’s expertise in computational optics, we may have just crossed a significant milestone.

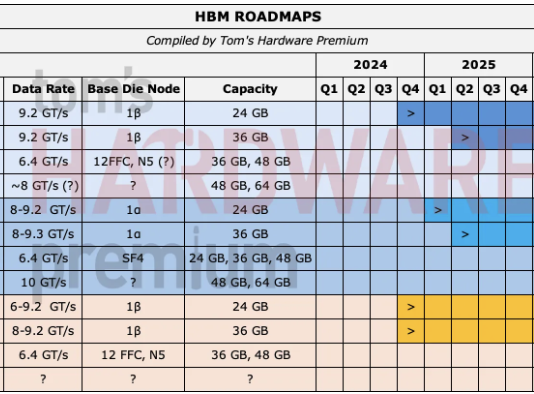

Traditional volumetric additive manufacturing cures high viscosity resins into solid shapes by projecting patterned light through the material as the object rotates 360 degrees on a pedestal. DISH adapts and extends on this principle with more precise, plus multi‑angle, light control. This is why computational optics is so important to the advance.

Instead of spinning the material, the DISH technique keeps it stationary, and instead uses a high-speed multi-perspective light field that rotates around the material. This enables the precise projection of complex 3D light intensity distributions in an extremely short time. Tsinghua’s advance thus allows for the headlining production of millimeter-scale objects in fractions of a second.

The scientists also claim there are stability and accuracy advantages to be had by moving the light field, rather than the material.

There is already talk about using DISH tech for mass production. The Chinese scientists reckon that this 3D printing technology would be eminently suitable for micro-components such as photonic computing devices and mobile phone camera modules, plus a multitude of parts which require sharp angles and complex curved surfaces. With an eye on the future, the scientists also say that DISH could be an asset in the production of complex components for flexible electronics, micro-robotics, and high-resolution tissue engineering.

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Get 3DTested's best news and in-depth reviews, straight to your inbox.