Can desktop recycling solve the 3D printer waste issue?

5 machines that promise to turn failed prints back into fresh filament

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

3D printing is no longer limited to a small group of dedicated tech enthusiasts. It has grown into a widely used tool among casually tech-savvy and creatively oriented makers. Affordable 3D printers and low-cost filament are enabling people to produce functional components, toys, and countless quirky trinkets more easily than before. But the excitement of having one of the best budget 3D printers in every home workshop has come with an unforeseen cost: overflowing bins of discarded filament and ruined prints.

The emergence of Bambu Lab’s AMS system turned four-color 3D printing into the standard for hobbyist creators. Why waste time painting your models when the printer can handle it for you? But despite recent advances in tool changers and interchangeable nozzles, many cost-conscious makers find it more economical to feed spools into their insatiable 3D printers than to upgrade to a filament-sipping Snapmaker U1 or Bambu Lab H2C.

On top of that, 3D-printed plastic is notoriously hard to recycle. Although standard PLA and PETG could be readily recycled, home-made parts lack resin identification codes. That means recycling centers can’t distinguish the plastic and will turn it away completely. Throwing away failed prints in your small blue bin will only pollute the recycling stream and send your failed prints straight to the landfill. And even when plastic is correctly labeled, many U.S. Cities continue to face challenges in locating buyers or processing facilities for low-value plastics, with some programs quietly stuffing local landfills full of recycling.

How do we manage waste generated by 3D printers?

Your choices are restricted if you aim to keep 3D printing waste out of the landfill. If you’re handy, you can melt your PLA scraps into silicone molds with a heat gun or toaster oven, though outcomes may differ. And truly, there’s not much of a market for 3D printer poop art.

Numerous filament manufacturers provide “recycled” PLA or PETG, though they usually reclaim waste produced by their own systems. Protopasta provides a budget-friendly black recycled PLA at $20 per kilogram, composed of leftover scraps from all their black productions, even those with glitter. Hardly anyone takes scraps from the community because of worries that the plastic isn’t properly sorted. A single PETG print in a PLA batch can create lumps that melt at different temperatures, potentially leading to jams and clogs in your 3D printer.

Printerior, based in St. Louis, MO ,, is among the limited number of filament producers that take in consumer-generated 3D printed PLA and PETG waste. The program is free, but if you’re not located nearby, you’ll need to cover the cost of shipping your scraps.

A standard industrial filament extrusion setup typically begins at $15,000 and can escalate dramatically beyond that. They also require enormous space and power, making them impractical for personal use.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

The idea that a desktop machine can perform the same task as a 75-foot industrial extrusion line seems implausible. But a pair of Italian inventors built a functional prototype using plywood and discarded computer components as early as 2014. You’d expect that twelve years on, we’d all own our own little “Mr. “Filament” machines positioned immediately beside our printers.

It ends up being somewhat of a mathematical challenge. A professional, high-quality setup requires thousands of dollars. You’d have to recycle hundreds of kilograms of scrap plastic just to reach break-even. Most enthusiasts don’t produce enough waste to justify the cost. Moreover, recycling filament demands careful sorting, thorough cleaning, and precise calibration to produce just one spool of material that won’t jam your printer.

As 3D printing moves into the mainstream, filament recycling is attracting increased attention. With an increasing number of potential customers drawn to a plug-and-play solution, the likelihood rises that a major manufacturer will take up the initiative.

Meanwhile, here are five 3D printing recycling machines you can buy today or imagine owning tomorrow.

Creality

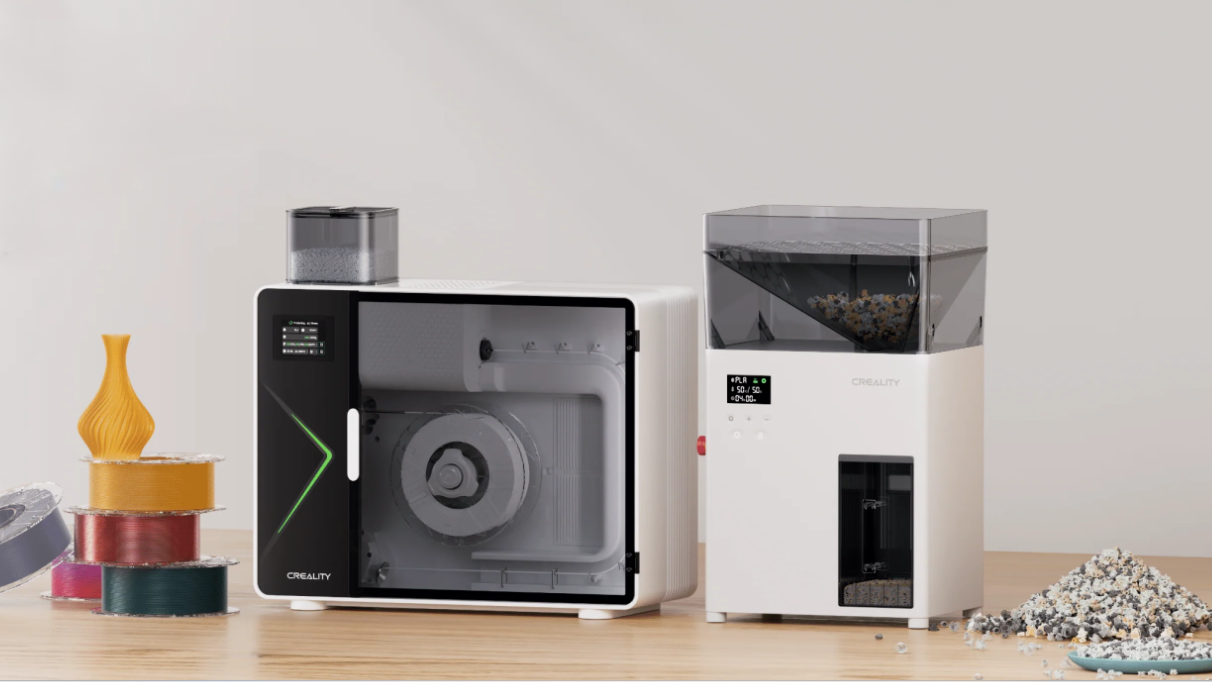

1. Creality Filament Maker M1 junto con la trituradora R1

Prototype

Price: Unannounced

Creality recently unveiled the Filament Maker M1 and Shredder R1, the first recycling system for consumers introduced by a leading 3D printing manufacturer. It’s a two-part system featuring a grinder that shreds and dries 3D printing waste, paired with a compact desktop extruder that can produce a one-kilogram spool in roughly an hour. The two units are available for individual purchase, allowing users interested solely in extruding fresh pellets to omit the shredder. Creality states tolerances as precise as ±0.05 mm using virgin material and ±0.1 mm with recycled grind. This is sufficient for most hobbyist printers, though it doesn’t quite match the quality of professionally manufactured filament.

The M1 remains in the prototype phase. Yet the product suggests that major manufacturers are prepared to address filament waste issues for their users.

LOOP

2. LOOP Desktop 3D Filament Maker

Launching 2026

Price: $100 deposit, Early Bird Price $1,489, Retail Price $2,499

LOOP’s idea was so bold that it was labeled a scam by YouTubers just after its announcement in 2024. Fortunately, LOOP’s modest team of Boston-based engineers replied by uploading a demo to YouTube to showcase a functional prototype.

LOOP is contained within a single unit, featuring a blender-style grinder on one side and a filament extruder on the other. It asserts a dimensional accuracy of.01 mm, with a tolerance range of +/- 0.07. Units were initially slated to ship in 2025, but the website now indicates a 2026 release. The project also touts itself as Open Source, which could strengthen its appeal among the DIY maker community.

We haven’t received any fresh updates since October 2024. If you become a backer with a $100 deposit, you’ll gain entry to a Discord channel featuring project updates and photos.

ExtrudeX

3. ExtrudeX DIY Kit

DIY Kit

Price: $59 to $239

We addressed the ExtrudeX while it was a Kickstarter, but now you can get this DIY kit for just $59, $180 worth of hardware, and a roll or two of ASA. You’ll also need to obtain your own grinder and a bag of fresh, unused pellets, since the designer suggests a 60-40 blend of new versus recycled material.

ARTME 3D

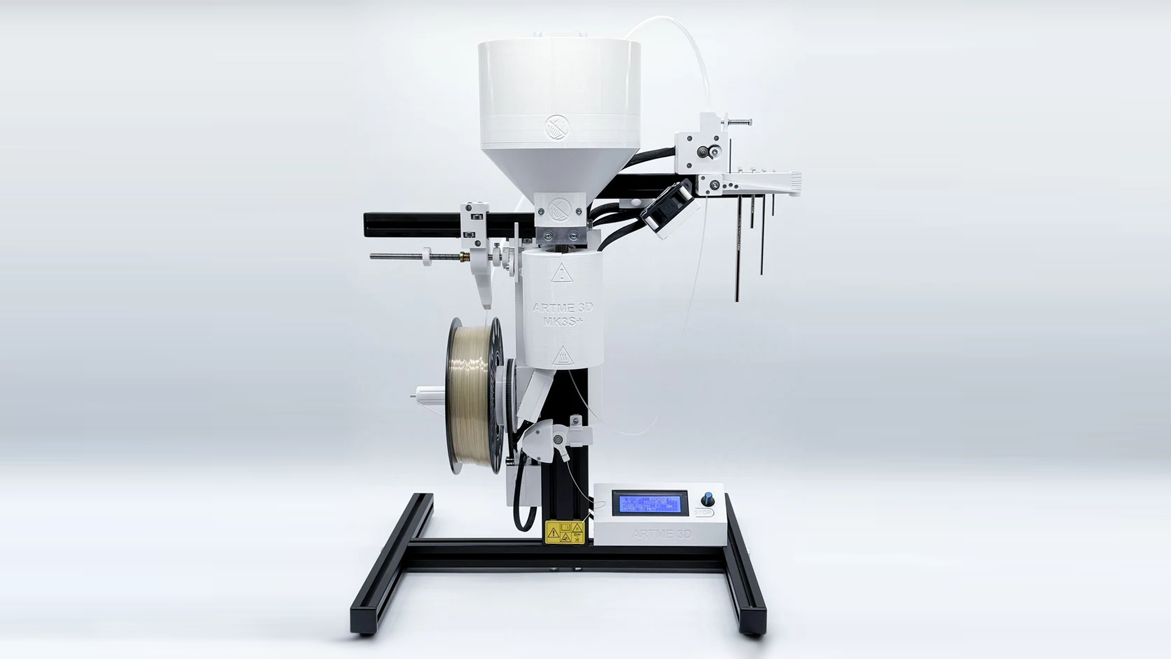

4. ARTME 3D DIY Kit

DIY Kit with printable parts

Price: $770 to $1,056

The ARTME 3D is a DIY kit manufactured in Germany for experienced makers. It comes with printed components and electronics, but users must provide their own 3D-printed parts. This is a fully operational machine that was demonstrated by CNC Kitchen in a video in 2023. It features an open-source design, and using printable components, it could be improved by a proficient builder.

The ARTME does not include a grinder or dryer. It melts PLA effectively, but users have noted challenges with PETG.

Felfil

5. Felfil Evo Extruder

DIY Kit or Complete System

Price: $699 to $2,999

Italy-based Felfil has spent years in the filament-making field with a modular, prosumer setup that divides the process into distinct tools: the Evo extruder, a spooler, and an optional shredder. It’s favored by universities and FabLabs and targets makers who are fine with experimenting. The hardware is reliable and accessible now, yet it still demands manual calibration and meticulous material preparation.

The Bottom Line

Desktop recycling won’t displace industrial systems anytime soon, but it’s no longer merely a niche garage project. Some of these machines are already functional, and even refined versions are coming soon, thanks to companies like Creality. For power users and makerspaces, the costs are beginning to add up meaningfully now. For everyone else, it signals that the industry is finally owning up to the waste it generates.

If the next wave becomes cheaper and simpler, your failed prints could turn into your next spool rather than ending up in the landfill.

MORE: Best Filaments for 3D Printing

MORE: Best 3D Printers

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

-

LordVile They don’t work. They don’t produce filament that’s uniforms enough of the correct diameterReply -

S58_is_the_goat Reply

Yup they're all junk.LordVile said:They don’t work. They don’t produce filament that’s uniforms enough of the correct diameter -

USAFRet Even if they did work well, you'd have to be very rabid with sorting the different types.Reply

Right now, the poop bucket behind my X1C has PLA, PETG, and ASA turdlets in it. -

Crazyy8 Reply

I'd assume it'd be better with bed slingers, since they can print fewer types of filament. I have an A1 and only use PLA and PETG. Both are vastly different colors, and could be easily separated.USAFRet said:Even if they did work well, you'd have to be very rabid with sorting the different types.

Right now, the poop bucket behind my X1C has PLA, PETG, and ASA turdlets in it.