3D printing with one of the world’s toughest tungsten-based materials is now feasible—the material’s exceptional hardness previously hindered additive manufacturing

‘Defect-free, industrial-grade carbides’ can be additively manufactured using a softening-not-melting approach devised by Hiroshima scientists.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Researchers at Hiroshima University have developed a new method to 3D print one of the toughest engineering materials utilized in industry.

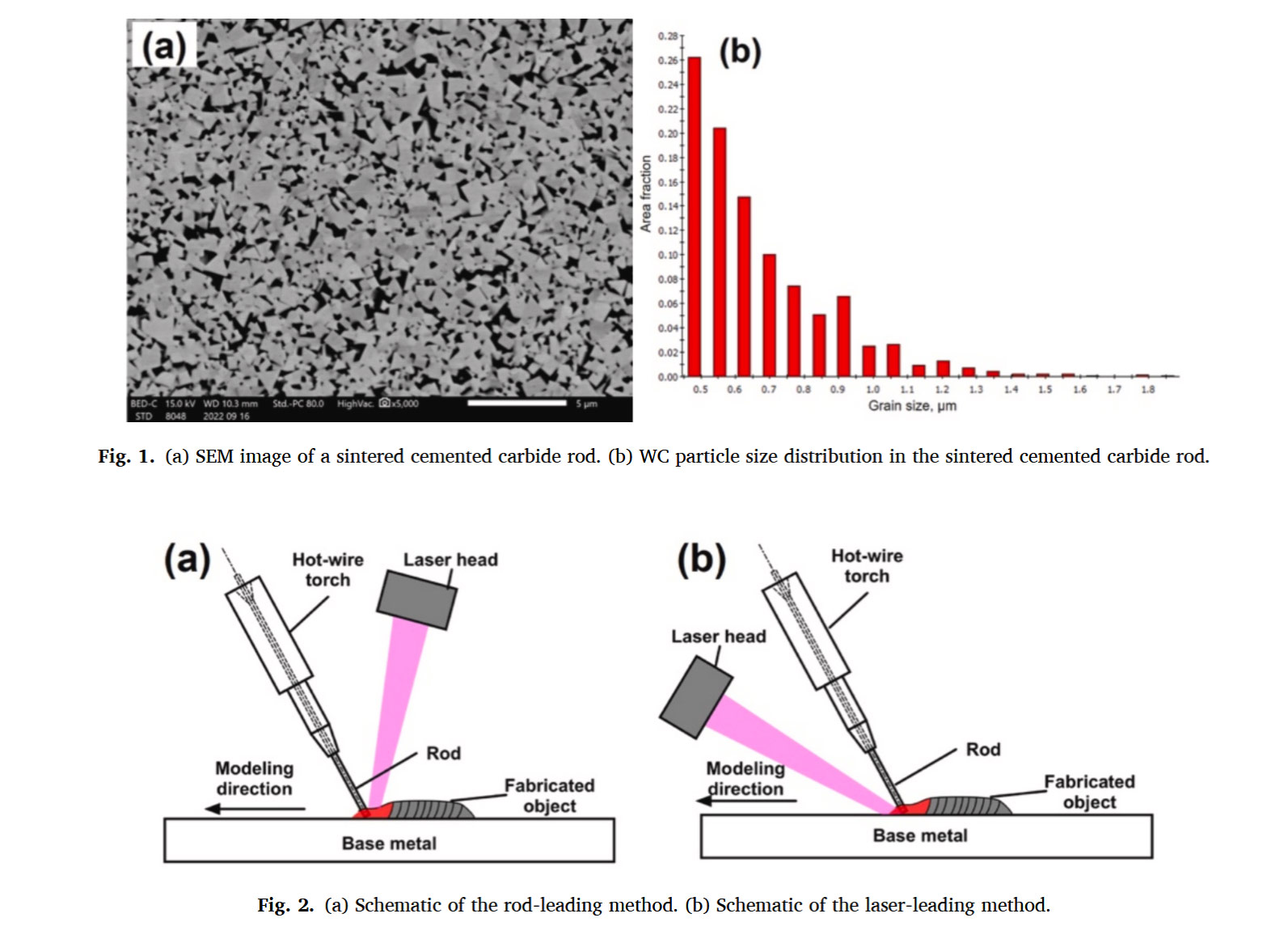

Ultra-hard materials are highly desirable for cutting and construction tools, but their inherent durability makes them exceptionally challenging to additively manufacture effectively. Rising to the challenge, Japanese researchers have successfully utilized the extremely durable tungsten carbide–cobalt (WC–Co) material in additive manufacturing “by softening them rather than fully melting them” during the Procedure. Moreover, the research team claims that this new 3D printing technology generates less waste than conventional manufacturing methods.

The Hiroshima University blog characterizes the WC-Co 3D printing process as a ‘hot-wire irradiation method.’ It is asserted that employing this hot-wire laser irradiation (also known as laser hot-wire welding) technique, a laser Beam gently heats a cemented carbide rod, avoiding complete melting and grain growth, to construct an additive manufactured structure. To obtain optimal results, a middle layer composed of a nickel-based alloy was placed between the additive layers.

Importantly, this ‘softening not melting’ approach ensures that the final 3D printed material maintains a “hardness of over 1400 HV, without introducing any defects or decomposition.” This hardness level is just below Extremely hard materials such as sapphire and diamond, and quite impressive for 3D printed results.

The method of shaping metal materials by softening them instead of completely melting them is innovative and could extend beyond cemented carbides—the focus of this study—to other materials,” said Keita Marumoto, an assistant professor at Hiroshima University’s Graduate School of Advanced Science and Engineering.

Moving forward, the research team, which also includes Takashi Abe, Keigo Nagamori, Hiroshi Ichikawa, Akio Nishiyama, and Motomichi Yamamoto, plans to introduce several process improvements. The scientists aim to resolve certain cracking problems encountered with the current process and refine it to produce more intricate forms.

3D printing with metals is significantly harder than printing with plastics, since metallic alloys demand very high temperatures and experience intricate thermal cycles and phase transformations during processing.

Get 3DTested's best news and in-depth reviews, straight to your inbox.

Follow 3DTested on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

-

hotaru251 hmm i do wonder what its limitations are since it can only be softened there must be someReply